Glass Strategies Presents

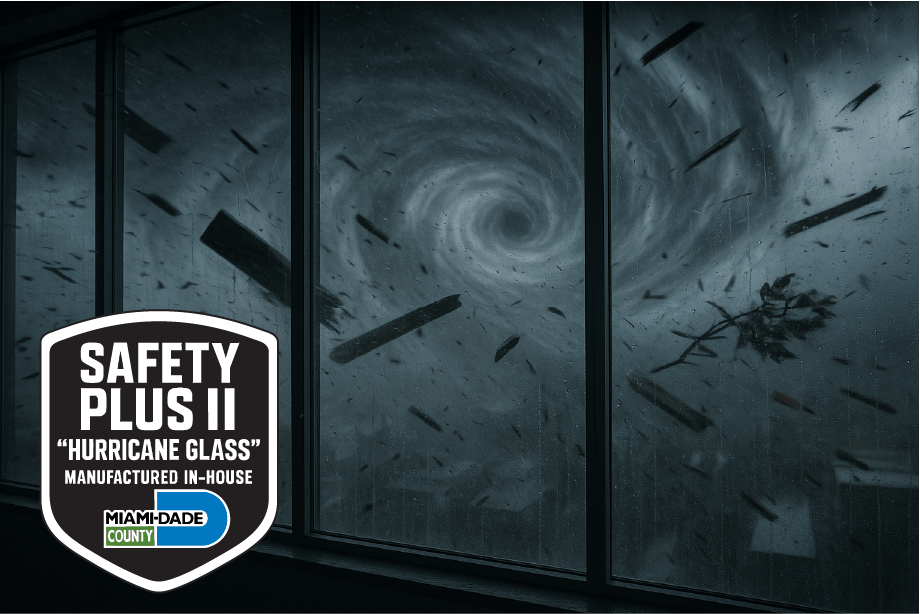

Safety Plus II ™

Impact-Resistant, Safety Laminated Hurricane/Storm Glass

Critical Compliance Alert for Contractors & Developers: The Mandate for Laminated Safety Glass is Here.

For construction professionals, understanding evolving building codes and insurance stipulations is not just good practice – it’s paramount to project success and risk management. Leading regulatory bodies and insurance carriers are increasingly making advanced laminated safety glass a non-negotiable requirement for new constructions and significant renovations. This isn’t a future trend; it’s the current reality for ensuring structural integrity, occupant safety, and long-term insurability. Non-compliance can lead to costly project delays, rejections during inspection, liability exposures, and even punitive measures, directly impacting your bottom line and reputation. Secure your projects and your business by integrating glass solutions that meet or exceed these critical new mandates from the outset.

Safety Plus II: Engineering Excellence That Surpasses Standards for Building Professionals.

Safety Plus II is engineered precisely for the demands of today’s commercial and governmental construction projects. As the product of Glasslam, a Polymer Extrusion Technology, Inc. company, our laminated glass is manufactured through a cutting-edge process that has earned Miami-Dade County certification. This rigorous approval is a clear indicator of compliance for the most challenging environments, including high-velocity hurricane zones, and demonstrates our adherence to the most stringent building codes.

While many products meet minimum specifications, Safety Plus II is designed to far exceed these new requirements. Our extensive testing, aligned with industry benchmarks like ANSI Z97.1 and 16 CFR 1201, confirms exceptional impact resistance and superior long-term stability. This means reduced risk of costly glass failures, enhanced security, and a durable solution that stands up to the most demanding conditions. For builders focused on quality, compliance, and delivering structures built to last, Safety Plus II provides a reliable, high-performance glazing strategy that minimizes risk and maximizes value.

Key Benefits of Safety Plus II Laminated Glass

-

Unmatched Impact Protection: Engineered for superior resistance against impacts, offering critical safety in high-risk areas and safeguarding occupants and property from flying debris.

-

Building Code Compliance: Achieves Miami-Dade County certification (NOA), ensuring compliance with the stringent Florida Building Code, including High-Velocity Hurricane Zone (HVHZ) requirements, essential for regulatory approval in storm-prone regions.

-

Enhanced Security: Provides an added layer of defense against forced entry, deterring intruders and increasing the overall security of commercial and government facilities.

-

Superior Durability: Designed for long-term stability with proven resistance to delamination, even under challenging environmental conditions, ensuring lasting performance and reduced maintenance.

-

Reliable Material Compatibility: Tested and proven compatible with common glazing materials like Dow 995 and GE SCS 2800 silicones, simplifying installation and ensuring system integrity.

-

Reduced Liability Risks: Incorporating certified safety glazing minimizes potential liabilities associated with glass breakage and non-compliance, protecting your project and your business.

-

Optimized for Commercial Use: Specifically manufactured for the demands of large-scale commercial and public building applications, offering a robust and reliable glazing solution.

Important Statistics & Certifications for Safety Plus II:

- Miami-Dade County NOA: Product holds NOA No. 24-0611.06, signifying compliance with rigorous building codes for High-Velocity Hurricane Zones.

- ANSI Z97.1-2004 Certified: Meets and passes impact requirements for safety glazing under ANSI Z97.1-2004, demonstrating adherence to industry safety standards.

- 16 CFR 1201 Compliant: Tested and approved to 16 CFR 1201 for safety glazing, affirming its performance in human impact scenarios.

- Exceptional Impact Resistance: Passed Class A impact tests, preventing a 3-inch sphere from passing through at an impact height of 48 inches.

-

Manufacturer: Proudly manufactured by Glasslam, a Polymer Extrusion Technology, Inc. company, using a Miami-Dade County certified system.

-

Water Immersion Resistance: Demonstrates no adverse effects on adhesion after 10 weeks of continuous water immersion, indicating excellent delamination resistance.

-

Structural Silicone Compatibility: Shows no negative effects when in contact with Dow 995 Silicone and GE SCS 2800 silicones.

-

Current NOA Expiration: The current Notice of Acceptance (NOA) for Safety Plus II is valid until August 7, 2028.